Order by 1 PM CT for Same-Day Free Shipping (Lower 48 | Mon-Fri)

At RAILBLAZA we are lovers of the ocean, and the outdoors in general. We’re lucky to have our head office in New Zealand, which has a very clean environment by world standards, and we’re determined to play our part in keeping it that way.

We take sustainability very seriously, and sustainability is a key input into all steps of our design process, from material selection to part design and packaging, we continuously ask ourselves “how can we minimise environmental impact?”

There are 3 key steps we follow to minimising the environmental impact of a product, most people will be familiar with the steps we use, they are known as the Three R’s Waste Hierarchy – Reduce, Reuse, Recycle. It’s important to note recycling is the last of these, as it occurs at the end of a product’s life, we want our products to be used by the consumer for as long as possible, to eliminate, or delay the need for recycling.

The primary sustainability goals of our design process are;

Other factors we consider during the design phase are;

The cost of the material is a secondary consideration in the design process and is only considered once we have established the material’s sustainability and suitability. This is one reason our products aren’t the cheapest on the market.

With packaging, it’s definitely the case that less is more!!

During the design phase we look at the packaging, and try to use the least amount possible, this helps both the user with lower costs, and the environment with reduced recycling and waste.

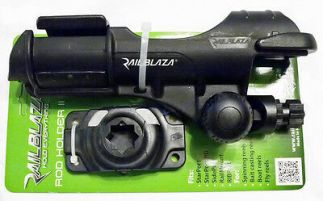

We always try to use cardboard as a first option, with plastics being the second choice. Recently we have changed the plastic we use for making our blister packs from PVC to PET. While PVC is recyclable, it is not recycled in many places. PET is what soft drink bottles are made from, meaning there are many more facilities processing this material for reuse.

“Every year we use hundreds of thousands of cable ties, and the offcuts were waste, going to landfill. With a bit of thought, we set up a system to turn them into knobs for rod holders and more.” Watch the video below to see a sample of this process

It takes a collective effort to make real change, we are proud to show how the companies sustainability goals are support by all of our staff. In our production warehouse, our staff even go so far as to bring in plastic containers from their homes to ensure they get REUSED as often as possible. Below is an example of icecream containers being utilised daily on the production line., every little bit counts and change starts with a combination of the many small things coming together.

“in our assembly plant we need a lot of plastic parts bins, but they don’t all need to be stackable. Where possible we re-use containers from elsewhere, like the above pic with ice cream containers that we use to hold screw packs and locking slides.” Mike Edgington – Production Manager

When you make the effort you often find you’re not alone – we take pride in working with suppliers who also make an effort and in the images below you can see our plastics supplier and hardware suppliers all happily accept the boxes back to be REUSED again and again. They simply pick them up on the next delivery run and put them back into the production line to be filled and sent out again

Here at RAILBLAZA we use a lot of stainless hardware for our hardware packs in the kits, they all come in boxes like these which are already labelled so makes sense to send them back ready to be refilled. It’s great to be working with suppliers that share the same goals to help make this possible.

A common sight around our production facility – boxes flat packed and boxes full of more boxes flat packed ready to go back into the supply chain.

Team RAILBLAZA at the 2019 Barracuda Tour © Julien Gazeau